EN 1090 Certified Subcontract Steel Fabrication Partner for European Contractors

Solve Your Capacity, Skill & Service Gaps with Metup – Certified Steel Fabrication Subcontract Partner

Metup scales with your needs

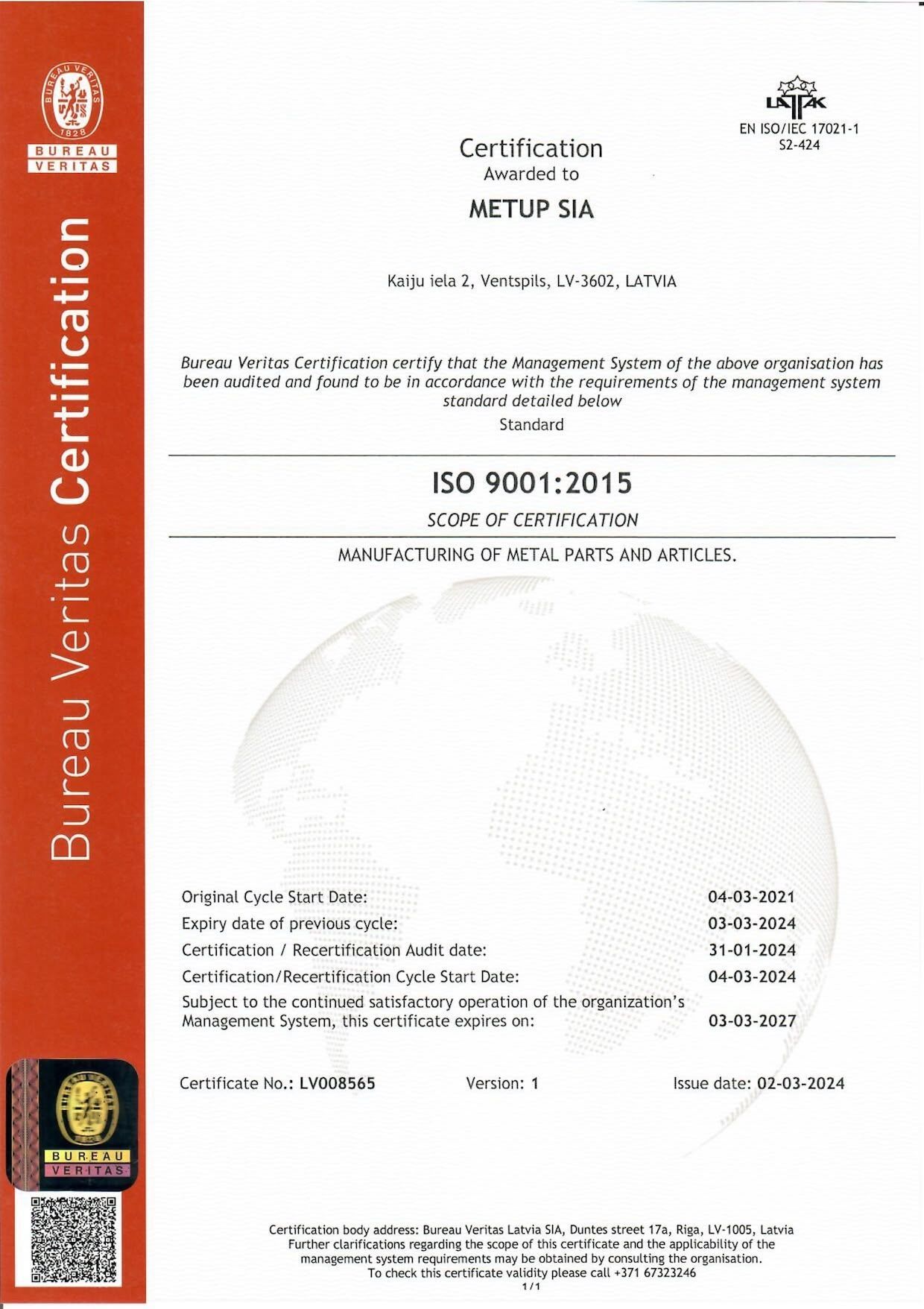

When your project pipeline exceeds in-house resources or requires certified specialty work, Metup is your confidential capacity extension—delivering EN 1090-2 EXC2 and ISO 9001 certified steel fabrication on time, every time. We support leading fabricators, general contractors, and EPCs in Central and Western Europe (e.g. Germany, Ireland), Scandinavia (Finland, Norway, Sweden, Denmark), and the Baltics.

Metup is the trusted “silent partner” behind successful deliveries across Europe: We operate under strict codes of conduct—never competing with our partners’ clients. Our role is to strengthen your reputation while managing risk.

Who do we Partner With

- Steel structure fabricators seeking overflow or specialized sub-contractor

- General and sub-contractors in the building and infrastructure sectors

- Machinery producers needing precision CNC-machined or welded components

- Technical design, engineering, and project management firms

- Private, municipal, and government infrastructure developers

- Landscape architects and public works project leaders

- Automotive and industrial manufacturers requiring reliable metal parts

Our Subcontractor Service Capacity

- Project size: from urgent one-offs to planned monthly batches (10–200t/month)

- Welding (MIG/MAG/TIG/laser/ bolt and spot welding), CNC machining, surface treatments

- Heavy frames to secondary assemblies—built to spec or standard

- Full documentation—EN/ISO certificates, load calcs, QA logs

Typical partner projects

- Load-bearing frames for commercial construction

- Custom welded assemblies for infrastructure

- Overflow component runs during peak months

- Complex or OEM Specific CNC Parts

Start Your Project

Request a Quote

Ready to expand your capacity—or need a reliable backup? Upload your drawings/specs below or book an intro call—our technical team responds within one business day.

Why Partner with Metup for Subcontract Steel Fabrication?

Flexible Surge Capacity

Easily scale production by 10–200 tons/month (ideal: 50–100t) to match your project demands.

QA & Traceability

Full quality assurance and material traceability, even for white-label or sub-contracted jobs.

Certified Structural Work

All projects adhere to EN 1090-2 EXC2 and ISO 9001 standards—no exceptions.

Seamless White-Label Service

Acting as an extension of your team, we ensure full confidentiality and brand consistency.

Advanced Engineering Toolkit

Top-tier CNC (HAAS/DOOSAN), laser/plasma cutting, and expert welding for any complexity.

Integrated Finishing & Logistics

Galvanizing, painting, and logistics all handled in-house for total project control.

Rapid, Transparent Onboarding

Quick start with pre-set NDAs/SLA templates and clear milestone tracking.

Confidentiality, Speed & Flexible Engagement

Your business stays protected:

- NDA signed at onboarding—your IP and client connections are secure

- SLA-driven delivery schedules; milestone tracking visible throughout project lifespan

- Onboarding from RFQ to production start in as little as 72 hours

- Transparent reporting at every stage—no surprises at handover

Start Your Project

Request a Quote

Ready to expand your capacity—or need a reliable backup? Upload your drawings/specs below or book an intro call—our technical team responds within one business day.

Technical Capabilities & Infrastructure

Welding Technologies

Utilizing MIG, MAG, TIG, Laserwelding, boldwelding, ans spotwelding processes to deliver exceptional quality in every weld.

CNC Equipment

Our modern HAAS and DOOSAN CNC machines enable us to produce precision components that meet the exact specifications of our clients.

QA/QC Systems

With an in-house inspection team we ensure that our products meet stringent quality assurance and control standards.

Capacity

We can handle up to 100 tons per month in-house, expandable to 200 tons with our partner network, accommodating project sizes from 10 to 200 tons.

Traceability Guaranteed

Every structure we fabricate is backed by a complete documentation set, ensuring full traceability and compliance with industry standards.

Consistent Performance

Metup delivers reliable performance year-round, keeping your projects on track regardless of the season.

Compliance & Documentation – Never Risk a Failed Inspection

METUP operates with full EN 1090-2 (up to EXC2) and ISO 9001 certification—ensuring every weld and component is compliant with EU requirements for structural integrity and quality management.

Every batch delivered by Metup comes with:

- Complete project records (EN 1090 / ISO 9001)

- Certificates of conformity; traceable batch/lot documentation

- Load/statics calculations; material certs (3.1)

- Documentation in English language, and beyond

Start a Partnership or

Send Your RFQ

Ready to expand your capacity—or need a reliable backup? Upload your drawings/specs below or book an intro call—our technical team responds within one business day.

Request for Quote

RFQ-Subcontracting

We will get back to you as soon as possible.

Please try again later.