Carbon & Stainless Steel Structure Fabrication –

EN 1090 EXC2 &

ISO 9001

MIG, MAG, TIG, Laser, Spot, Bolt welding

- Sweden & Nordics Delivery

- Winter ops, full service

- WPS/WPQR & QA Docs

- Welding capacity 10–200t/mo

- Subcontracting/Overflow

Ready

Upload drawings / Request RFQ

Submit your question, files, email, and phone (optional) and we'll get back to you in a day.

RFQ-Welding-Fabrication-Quick

We will get back to you as soon as possible.

Please try again later.

Industries We Serve

At Metup SIA, we specialize in delivering high-quality steel framework solutions tailored to businesses of all sizes across diverse industries. Our expertise guarantees precise and reliable results that meet the unique demands of each sector.

Warehousing & Logistics

Robust steel structures designed to optimize storage and logistics operations

Factories & Manufacturing

Steel frameworks are engineered to support heavy machinery and production lines

Public Infrastructure

From bridges to walkways - steel solutions that meet safety standards for public infrastructure projects.

Machinery Frames & Heavy Equipment Bases

Strong and reliable frames that support heavy equipment for in demanding environments.

Hangars & Large-Span Buildings

Large-span steel structures for spacious and functional hangars tailored to your specific needs.

Custom-Engineered Projects

Bespoke steel solutions complient with industry standards and your unique project requirements.

Welding Services for Demanding Projects

At Metup, we deliver certified steel structure fabrication and welding services designed for demanding construction, industrial, and infrastructure projects across Denmark, Germany, Scandinavia, the Baltics, and Central and Western Europe. From engineering concept to on-site assembly, our team ensures every detail meets your technical requirements and regulatory obligations.

Project Capacity

Our projects range from 10–200 tons per project.

Best project fit: 50–100t

Up to 100t/month in-house – scalable to 200t with partner network.

All-Year Operation

Full-Service Delivery

From Design and Fabrication, to Delivery & Quality Assurance – Documentation Included.

Design & Engineering

Collaborative planning; load calculations; compliance consulting.

Fabrication & Welding

Collaborative planning; load calculations; compliance consulting.

Quality Assurance

Non-destructive testing (NDT); continuous QA/QC checks.

Surface Treatment

Hot dip galvanizing, painting/coating as required.

Logistics & Delivery

Cross-border delivery; on-site installation support.

Documentation Included

Full technical records in client’s language; audit-ready files.

Start Your Project

Request a Quote

Ready to discuss your next steel structure project? Submit your drawings/specs or book a consultation—our engineers will respond within one business day.

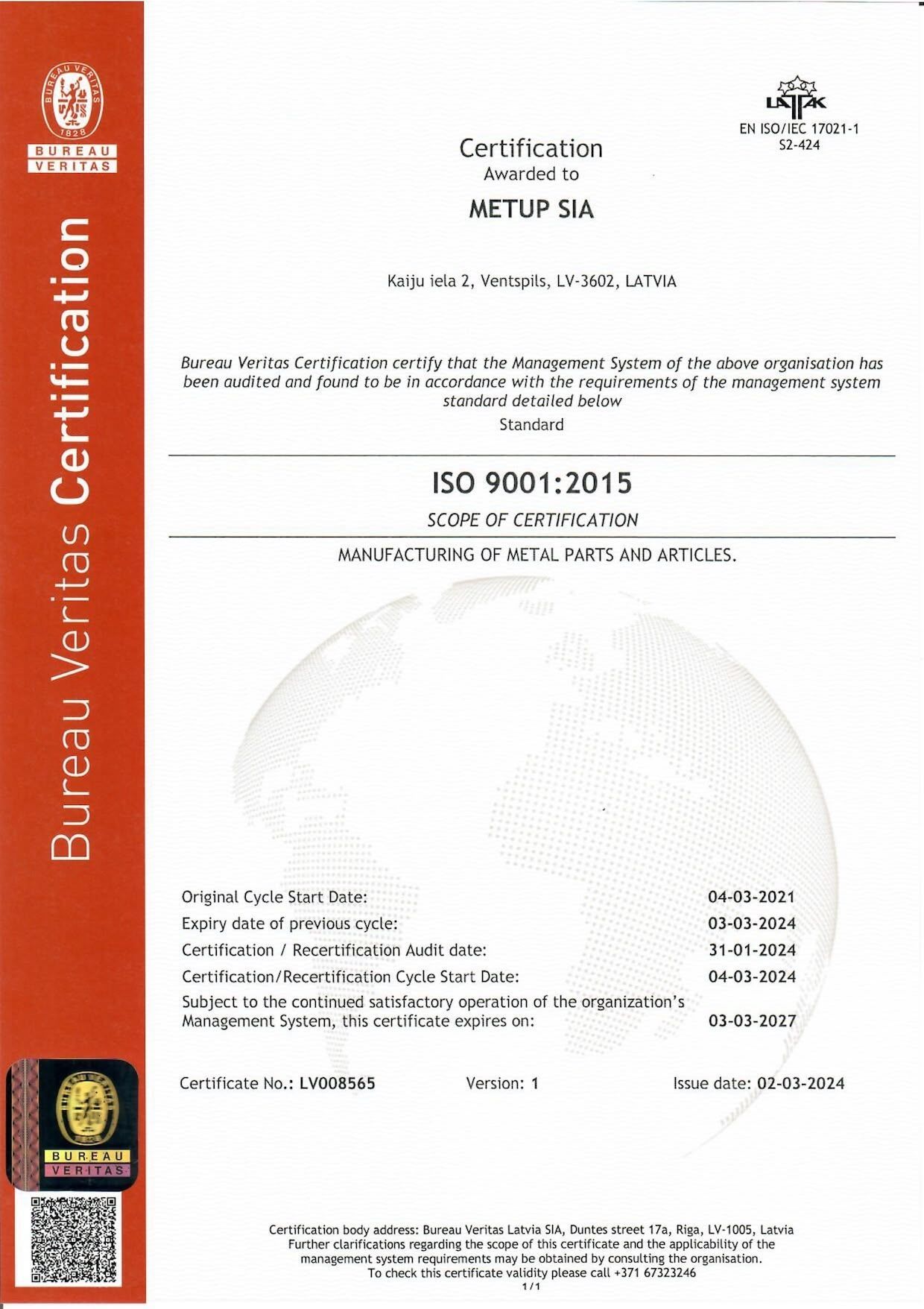

Our Certifications & Compliance Guarantee

METUP operates with full EN 1090-2 (up to EXC2) and ISO 9001 certification—ensuring every weld and component is compliant with EU requirements for structural integrity and quality management.

What this means for you?

- Accepted on major projects throughout EU, Denmark, Germany, Scandinavia

- Immediate regulatory acceptance—no delays at inspection or handover

- Full traceability: material certificates (3.1), weld logs, QA records provided as standard

- CE marking included on all qualifying structures

Technical Capabilities & Infrastructure

At Metup SIA, we are built for demanding projects, leveraging advanced welding technologies and state-of-the-art equipment to deliver exceptional results. Our welding capabilities include MIG, MAG, and TIG processes, laserwelding, boltwelding, spotwelding. We ensure precision and quality in every weld, meeting the rigorous standards of the construction industry.

With an in-house inspection team we guarantee quality assurance and control throughout the production process.

Welding Technologies

Utilizing MIG, MAG, TIG, Laserwelding, boldwelding, ans spotwelding processes to deliver exceptional quality in every weld.

Equipment

MIG/MAG, TIG, Laserwelding, boltwelding and spotwelding stations, overhead cranes with lifting capacity up to 30 tons, band saw up to 400 mm diameter, balsting and wet painting facilties.

QA/QC Systems

With an in-house inspection team , we ensure that our products meet stringent quality assurance and control standards.

Capacity

We can handle up to 100 tons per month in-house, expandable to 200 tons with our partner network, accommodating project sizes from 10 to 200 tons.

Traceability Guaranteed

Every structure we fabricate is backed by a complete documentation set, ensuring full traceability and compliance with industry standards.

Consistent Performance

Metup delivers reliable performance year-round, keeping your projects on track regardless of the season.

TIG Welding

Ultra-clean, precision welds for stainless steel and intricate components.

MIG Welding

Fast, efficient welding for thin or medium metal parts—perfect for quick-turn projects and cost-effective assembly of non-ferrous materials.

MAG Welding

High-strength, deep-penetration welds on carbon steel—best for robust structural steelwork and heavy-duty industrial components.

Laserwelding

Maximum precision and speed for thin, heat-sensitive metals—delivers flawless, automated welds in high-tech, intricate assemblies.

Spotwelding

Rapid bonding of overlapping thin sheets—top choice for automotive panels and scalable repetitive manufacturing.

Boltwelding

Fast, secure stud or bolt attachments—saves time and ensures durable connections in modular steel construction.

Request for Quote

Ready to discuss your next steel structure project? Submit your drawings/specs or book a consultation—our engineers will respond within one business day.

RFQ-Welding-Fabrication

We will get back to you as soon as possible.

Please try again later.